Flour bags introduction:

1. Paper flour bags

As a bio-degradable material, combined with modern moisture-proof technology, can provide flour high-strength protection and excellent eye contact. Paper material is the most popular product in flour packaging.

Normally 1kilo 2kilos 3kilos paper bags made of one layer kraft paper of thickness 60-120gsm. 5kg-10kg use 2ply paper bags for packaging, 15kg 20kg 25kg use 3layers paper material to bear heavy loading and good shape.

Paper bags suitable for general household and commercial use with relatively low costs.

2. Composite / laminated paper flour bags

Coated flour bags has good moisture resistance for loading more than 50kilos weight. It is recyclable and environmentally friendly material, suitable for occasions with high environmental requirements.

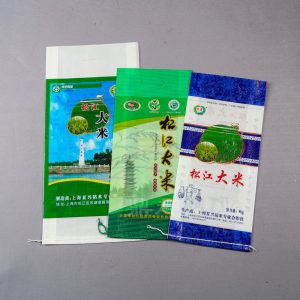

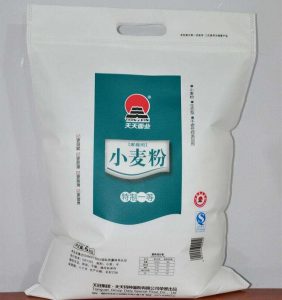

3. Plastic flour bags (including polypropylene, polyethylene, Nylon etc.)

Plastic bags has excellent sealing performance, moisture proof and anti-leakage, protecting the flour from dampness and contamination. PE PP bags are suitable for the long term storage and transportation of flour in various environments, especially in areas with high humidity.

4. Non-woven fabric flour bags:

Non woven bags with good breathability, does not react with inner flour, commonly used for high-quality flour packaging. They are always keep the freshness and taste of the flour, suitable for both household and commercial use.

In selecting flour bags, in addition to the material, thickness, durability, and sealing methods should also be considered to ensure the quality and safety of the flour.

Flour bags can also be printed and designed to enhance brand image and market competitiveness. Exquisite designed flour bags can not only attract consumers’ attention, but also enhance the value of products.